Oil Immersed Circuit Breaker

Low Voltage Oil Immersed Circuit Breakers provide complete protection to Distribution Transformers from over-load, over-current, short-circuit and over-heating thus reducing the damage levels and help in reducing maintenance cost. The Oil immersed circuit breakers are designed using top notch technology and high-grade raw materials resulting in superior performance and maximum working life.

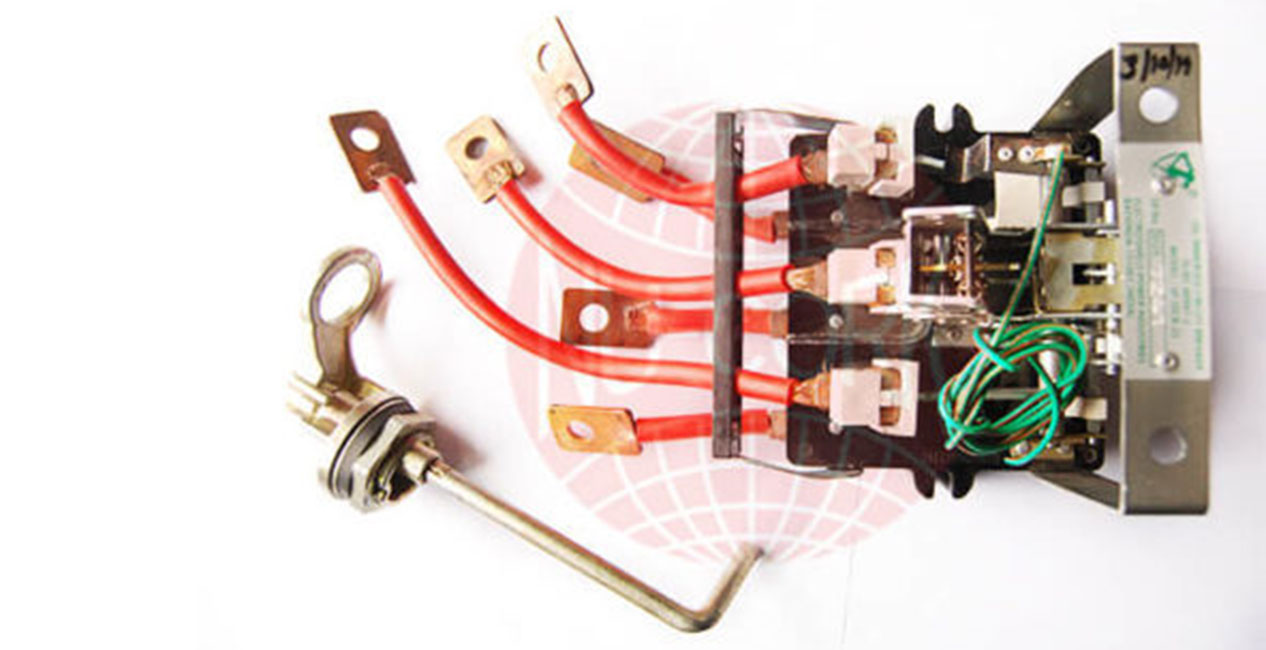

The Oil immersed circuit breaker is mounted inside the transformer above core coil assembly and is connected to external operating handle via connecting rod. The input leads of breaker are connected to Low Voltage/Secondary Winding and the output leads are connected to Low Voltage Bushing Terminal of Transformers. It is the central component of CSP (Completely Self Protected) Distribution Transformer protection system. There is thermal coordination between the transformer’s windings and breaker, so that it trips only when it is necessary to protect the transformer windings from excessive overloads and external faults. The Oil immersed Circuit breaker enhances the load capability of transformer all the times by permitting the transformer to deliver as much load as it is capable of without damaging its insulation system.

CSP technology has laid the path for better distribution system management and high performance distribution transformer. Since overloading is unavoidable feature of Power sector, the use of Oil Immersed Circuit Breakers ensures enhancing the working life of the distribution transformers.

Oil Immersed Circuit Breakers have following advantages:

Connecting Leads are made from Standard Cross-Sectional Area Copper Braids of such lengths that there is no need of any joint to connect to transformer terminals.

The tripping mechanism is completely joint free.

Superior Mechanical Strength ensuring ruggedness during entire working life of transformer.

Superior Insulation of contacts leads to ensure high insulation levels and longer life in transformer oil.

Signal Light Wire length is being provided so as to make joint free loop making.

Contact points/terminals are of bigger size resulting in increased area of contact thus reduced resistance.